Maximizing the longevity of die casting molds is a critical consideration for manufacturers aiming to enhance production efficiency and reduce costs. The strategic selection of materials, coupled with advanced cooling techniques and regular maintenance, plays a pivotal role in extending mold life. However, the intricacies of tool design and the implementation of preventive measures often remain underexplored. Understanding these elements can yield significant benefits, but the path to achieving ideal mold longevity is not straightforward. What specific strategies can be employed to navigate these complexities effectively?

Understanding Die Casting Tooling

What exactly constitutes die casting tooling?

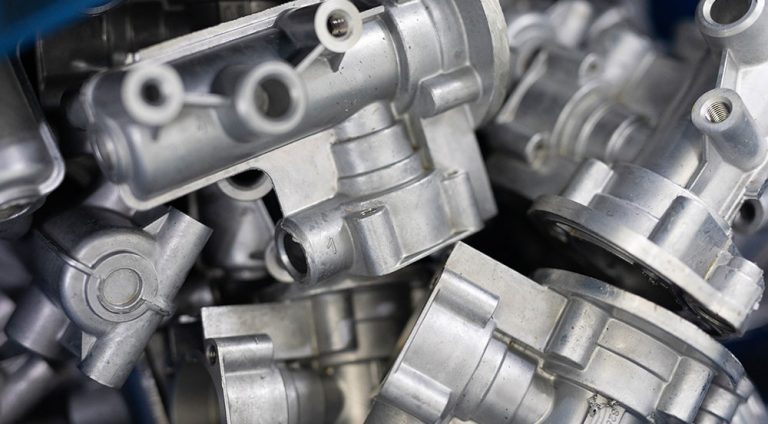

Die casting tooling is a specialized system that includes a die cast mold designed with a cavity for the injection of molten metal. The efficiency of this tooling technology depends on the selection of appropriate mold materials, which are essential for withstanding high temperatures and pressures during the casting process.

The tooling separates into multiple pieces after the metal solidifies, facilitating the removal of the finished casting. Different tooling methods, such as proprietary multi-slide and conventional designs, offer unique advantages tailored to specific project requirements.

Significantly, utilizing advanced technologies like 3D Metal Flow Simulation can enhance the gating system and reduce porosity in the final products.

Ultimately, the quality of die casting tooling directly influences the overall effectiveness and efficiency of the casting operation, making it a critical aspect of the manufacturing process.

Importance of Tool Design

Effective tool design serves as the foundation for successful die casting operations, directly impacting both productivity and product quality. Emphasizing design innovation and material optimization is vital in creating molds that withstand the rigors of repeated use.

Well-designed tooling not only enhances casting accuracy but also reduces cycle times, ultimately leading to increased throughput. Key considerations, such as thermal management and precision in geometry, are essential for maximizing mold longevity.

Consistent wall thickness is another vital factor, ensuring structural integrity and reducing defects. The integration of advanced materials can further enhance durability, mitigating wear from high-temperature cycles.

Strategies for Tool Maintenance

Maintaining die casting tools is essential to preserving their longevity and ensuring consistent production quality. Implementing a robust preventive maintenance program is imperative; it involves regular scheduling of maintenance tasks to address wear and tear before they escalate.

Leveraging advanced die casting technologies can also play a key role in minimizing wear by optimizing processes and materials used. Frequent tool inspections are essential, allowing for early identification of potential issues such as gate erosion or core wear. These inspections should include a detailed assessment of wear patterns and operational efficiency.

Additionally, maintaining a clean environment around tooling can greatly reduce contamination risks that lead to premature wear. By prioritizing these strategies, manufacturers can minimize downtime, enhance tool performance, and extend the overall lifespan of their die casting molds, ultimately contributing to improved production efficiency and cost-effectiveness.

Enhancing Tool Durability

Durability is a crucial factor in the performance and lifespan of die casting molds, influencing both production efficiency and cost management. Selecting appropriate tool materials, such as high-quality steel or specialized alloys, enhances resistance to wear and thermal fatigue. These materials can greatly withstand the intense conditions experienced during the die casting process.

Moreover, implementing advanced cooling techniques plays an essential role in maintaining ideal temperatures within the mold. Efficient cooling not only reduces thermal stress but also minimizes the risk of defects in the final cast product. By combining the right materials with effective cooling strategies, manufacturers can guarantee extended tool durability, ultimately leading to improved production rates and reduced operational costs.

Additionally, incorporating mold flow analysis in the design phase can help predict and address potential issues, further enhancing the mold’s longevity.

Maximizing Return on Investment

Maximizing return on investment (ROI) in die casting requires a strategic approach that encompasses high-quality tooling, efficient design processes, and proactive maintenance.

Utilizing superior tooling materials markedly enhances mold durability, thereby extending its lifespan and reducing replacement costs. Companies like Kenwalt Die Casting, with their commitment to excellence, exemplify the benefits of investing in robust, well-designed tooling, which not only guarantees consistent production quality but also minimizes downtime associated with repairs.

Implementing rigorous maintenance schedules is essential for monitoring tool conditions and mitigating wear from repeated heating and cooling cycles. By prioritizing both the selection of premium tooling materials and regular upkeep, manufacturers can optimize their ROI.

Ultimately, a focus on quality and maintenance translates to enhanced productivity, reduced scrap rates, and increased profitability in die casting operations.